Asphalt concrete is the most widely used construction material in the world for paving roads, airfields, and parking lots. However, conventional asphalt concrete has several limitations, including low durability and low resistance to traffic loads and environmental stress, which result in frequent repairs and early replacement. In recent years, Stone Mastic Asphalt (SMA) has emerged as an alternative to conventional asphalt concrete that offers several advantages, including higher durability, improved resistance to traffic loads and environmental stress, and longer service life.

What is Stone Mastic Asphalt?

There are three major types of asphalt surfacing, characterized by a mixture of bitumen and stone aggregate.

- Dense Graded Asphalt (DGA),

- Stone Mastic Asphalt (SMA) and

- Open Graded Asphalt (OGA).

Stone Mastic Asphalt (SMA) is a type of gap-graded asphalt mixture that consists of mineral aggregate (coarse and fine aggregates), filler, bitumen (binder), and air voids. Mostly, an SMA mix design uses modified bitumen and also includes a small percentage of fibre. The mineral aggregate used in SMA is typically angular and well-graded, and the air voids are deliberately left in the mixture to provide a deformable matrix that can resist heavy traffic loads and environmental stress.

Stone Mastic Asphalt Composition

| Material | Function |

| Coarse Aggregates | Provides the strength of the mix via stone-to-stone skeletal interlock. |

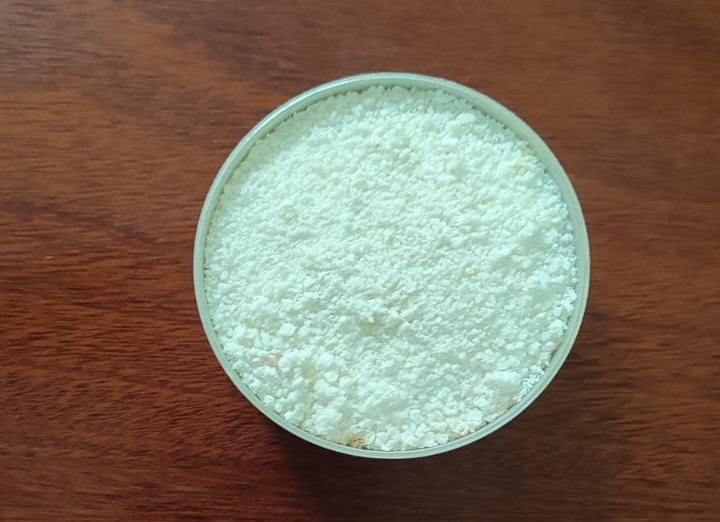

| Fine aggregates & Filler | – Improves the stability of the SMA mix by filling the gaps between the coarse aggregates. – Improves workability and adhesion of the mix. – Examples of filler material include hydrated lime, fly-ash and natural filler, such as very fine quarry dust. |

| Modified Bitumen | – Bitumen acts as the binder in an SMA mix, binding the various components of the mix together. Modification of the bitumen improves the flexibility and crack resistance of SMA, regardless of temperature fluctuations. – Some of the modifiers used include thermoplastics, synthetic thermohardening resins, powdered rubber from discarded tyres and elastomers. |

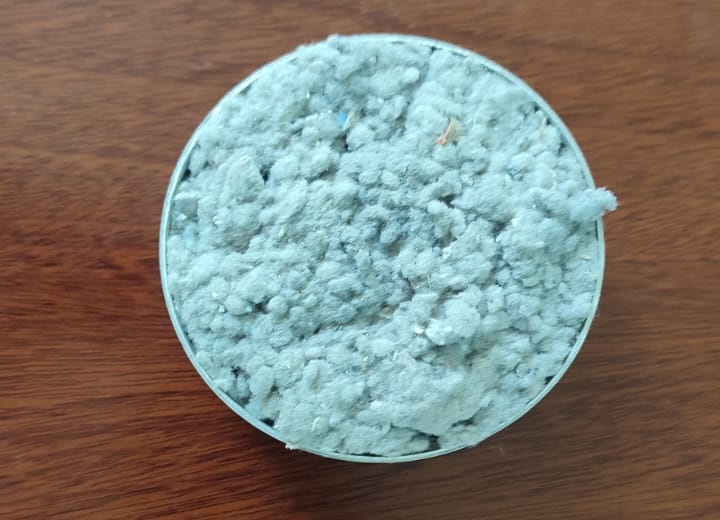

| Fibre | Fibre has the main purpose of preventing binder drain-down during transportation and laying. It also serves to improve the strength of the pavement. |

Typically, the air voids in any hot mix asphalt pavement layer should never fall under 3% at refusal density. Unlike conventional asphalt concrete, which is typically compacted using both steel drum and pneumatic rollers, SMA is compacted using only steel drum rollers, which provide a high degree of compaction and helps to achieve the desired air void content and mechanical properties. Pneumatic rollers are not applicable when compacting SMA pavement layers due to the following reasons:

- Potential for Aggregate Displacement: The use of pneumatic rollers on SMA might lead to aggregate displacement of the coarse aggregates, disrupting the stone-on-stone contact that is crucial for the strength and stability of SMA.

- Risk of Binder Pickup: Ideally an SMA mix has higher binder content compared to conventional AC, exacerbating the risk of binder pick up by the rubber tires, leading to loss of binder from the surface and reducing the effectiveness of the compaction process.

- Surface Texture Issues: The main function of pneumatic rollers on asphaltic pavements is to provide the kneading action on the mix, helping to achieve a uniform density and improving the interlock between aggregates and binder. This process also leads to a smoother finish which can potentially lead to problems with surface drainage and skid resistance. It is important to note that whereas most conventional AC layers often receive a top finish of skid-resistant surface dressing, this is not necessary for SMA surfacings.

Bitumen Modifier Characteristics

As was mentioned in the preceding sections, different types of modifiers can be used in the production of SMA. The choice of the modifier to use is dependent on several factors including its availability and cost, but ultimately the modifier chosen should have the following properties:

- Resists degradation of Bitumen at Mixing Temperature,

- Be compatible with bitumen,

- Be capable of being processed by conventional mixing and laying machinery,

- Produce coating viscosity at application temperature,

- Maintain premium properties during storage, application and in-service, and

- Be cost-effective on a life-cycle-cost basis.

Production and Laying of Stone Mastic Asphalt

SMA is produced in a hot mix plant, with the modifier introduced directly into the bitumen after heating it to between 150oC and 170oC. Care should be taken not to heat the bitumen beyond 170oC. Beyond 170oC, one runs the risk of the bitumen undergoing thermal cracking which can lead to a decrease in the performance of the asphalt mixture. It is important to note that in some cases, one can purchase the bitumen already premixed, without the need for the modification of an already existing asphalt plant for the production of SMA.

The fibre is added directly to the mix, at the point of introduction of the aggregates, which is done at between 190oC and 220oC. The laying temperature for SMA should not be less than 160°C. Compaction is done by heavy compaction equipment and pneumatic rollers are not suitable. The temperature after the laying operation must not be less than 90°C. SMA pavements can only be opened to traffic once the temperature of the mix in the pavement is under 40oC, to prevent the flushing of the binder to the surface.

Some of the notable differences between Stone Mastic Asphalt and conventional AC are highlighted in the table below:

| Stone Mastic Asphalt | Conventional AC |

|---|---|

| High proportion of coarse aggregates (typically >65%) | 40% to 60% coarse aggregates |

| High binder content (> 6.5 ) | Generally under 6% |

| Addition of stabilizing additives such as fibre | No additives required |

| High stability and durability | Balanced/compromise for strength and durability |

| Excellent rut resistance | Good rut resistance |

| Noise reduction on the riding surface | Noisy riding surface. |

| Requires heavy compaction equipment – no pneumatic rollers required. | Light and medium compaction equipment required – pneumatic rollers used to knead the mix |

Advantages of Stone Mastic Asphalt

There are several advantages to using Stone Mastic Asphalt as an alternative to conventional asphalt concrete, including:

Higher Durability: Stone Mastic Asphalt has a higher resistance to traffic loads and environmental stress, which results in longer service life and reduced maintenance costs. The angular and well-graded aggregate used in SMA provides a stronger matrix that can resist heavy traffic loads and environmental stress, and the higher air void content provides a deformable matrix that can absorb stress and reduce the risk of cracking and rutting.

Improved Resistance to Traffic Loads and Environmental Stress: Stone Mastic Asphalt has a higher resistance to traffic loads and environmental stress. SMA depends on the aggregate-to-aggregate interlock, as opposed to conventional asphalt concrete whose mix designs contain relatively smaller proportions of coarse aggregates. This aggregate-to-aggregate interlock is where SMA derives its strength, with minimal rutting and deformation expected during the service life of the pavement.

The higher proportion of coarse aggregates contained in SMA translates to higher voids within the mix, what is referred to as the Voids in Mineral Aggregates (VIM). The Voids in Mineral Aggregates are partially filled in with the bitumen binder, with the remaining voids referred to as the air voids. With the Voids in Mineral Aggregates being significantly higher for SMA than for conventional AC, more bitumen in SMA is required than in conventional AC. However, a delicate balance exists in the relationship between the proportion of bitumen in the asphalt mix and the probability of rutting of the pavement upon secondary compaction by traffic during its service life, especially in hot climates. This type of failure is known as plastic deformation. On the other extreme, reducing the quantity of bitumen in the mix below a certain threshold leads to the rapid oxidation of the bitumen and failure of the asphalt layers through cracking.

With the above contradicting mix design requirements, material engineers came up with an innovative solution to ensure that asphalt pavements perform in a satisfactory manner, even under extreme traffic loading and weather conditions. The modification of bitumen by the addition of a polymer and some fibre material in the asphalt mix enhances the strength of the mix. Using polymer-modified bitumen means that the pavement structure can withstand higher traffic and environmental loads without deforming or cracking, as conventional AC would do.

I have had the privilege of working on two projects within Coastal Kenya whereby Stone Mastic Asphalt technology has been used in the construction of the road pavement. In these projects, the binder modification was done using a thermoplastic copolymer known as Styrene Butadiene Styrene (SBS), known for its ability to maintain its flexibility and elasticity over a wide temperature range, making it suitable for applications that require a combination of rigidity and flexibility. Further, the bitumen was impregnated with cellulose fibre, a natural polymer derived from plant materials, mainly from wood pulp. Cellulose fibre is renewable, biodegradable, and environmentally friendly, making it a desirable alternative to synthetic fibres in many applications. As mentioned earlier, an SMA mix contains significantly higher binder content than traditional AC. Therefore, the addition of fibre in the SMA mix, apart from increasing the strength of the pavement, also serves to prevent binder drain-down while transporting and laying.

Longer Service Life: Stone Mastic Asphalt has a longer service life compared to conventional asphalt concrete, which results in reduced maintenance costs and improved road user satisfaction. The improved durability of SMA reduces the need for frequent repairs and replacement, and the longer service life of SMA reduces the need for frequent resurfacing and rehabilitation.

Improved Workability: Stone Mastic Asphalt is easier to work with compared to conventional asphalt concrete, which results in improved construction quality and reduced construction time. The higher air void content of SMA provides a deformable matrix that is easier to compact, which reduces the risk of cracking and improves the overall quality of the pavement. Furthermore, less equipment and manpower is required to lay SMA as opposed to conventional AC.

Improved Sustainability: Stone Mastic Asphalt is a more sustainable alternative to conventional asphalt concrete, which reduces the environmental impact of road construction and maintenance. The longer service life of SMA reduces the need for frequent resurfacing and rehabilitation, which reduces the amount of material required and the amount of waste generated.

Some of the drawbacks to the use of Stone Mastic Asphalt pavements include:

- Increased cost associated with higher binder and filler contents, and fiber and polymer additives,

- High filler content in SMA may result in reduced productivity. This may be overcome by suitable plant modifications,

- Possible delays in opening to traffic as SMA mix should be cooled to 40oC to prevent flushing of the binder to the surface, and

- Initial skid resistance may be low until the thick binder film is worn off the top of the surface by traffic.

Generally, though, Stone Mastic Asphalt is a promising alternative to conventional asphalt concrete that offers several advantages, including higher durability, improved resistance to traffic loads and environmental stress, longer service life, improved workability, and improved sustainability. While SMA may be more expensive to produce compared to conventional asphalt concrete, the increased durability and longer service life of SMA offset the higher initial cost and result in reduced maintenance costs and improved roads.

SMA is the way to go: great article engineer!

Indeed it is. As African countries, we need to catch up with these technologies early on. European countries have been using this technology since the 1960s and we are just catching up with it now. Additionally, we must also encourage a lot of research, especially in the field of material science, to come up with tailor-made solutions specific to Africa.

Thanks for sharing such informative article. Looking forward to more of your works!

Thanks for appreciating my work Citi. Keep it here for more.

Which are the Kenyan roads constructed using this technology?

The Kenyan roads constructed using this technology already are i) Mombasa CBD to Kwa Jomvu (completed) ii) Mtwapa to Kilifi (under construction) iii) Mombasa (Kengeleni) to Mtwapa (under construction) and iv) Kwa Jomvu to Mariakani (under construction)