Apart from the California Bearing Ratio (CBR) discussed in a previous article, another method used for determining subgrade strength is the Dynamic Cone Penetrometer (DCP) test. As opposed to the CBR test, DCP tests are used for the determination of in-situ site conditions (either compacted or at natural state). The DCP is a quick, in-situ test ideal for rapid field evaluations and quality control during road construction, providing immediate results by measuring the penetration rate of a cone into the soil. In contrast, the CBR test is more time-consuming and typically conducted in the lab, offering a more standardized measure of soil bearing capacity, often required for pavement design approval by regulatory bodies. While DCP is practical for on-site decision-making, CBR is preferred for formal design validation. While the CBR test is more accurate and therefore the preferred method for the determination of subgrade strength, certain scenarios can limit the engineer to use the DCP test.

The DCP test involves driving a steel cone into the ground using a standard weight dropped from a fixed height and measuring the depth of penetration per blow. The shear strength measured by the test is then correlated with the California Bearing Ratio (CBR) or Unconfined Compressive Strength (UCS) by using specific graphs or empirical relationship formula. The accuracy of the DCP test, however, is affected by several factors including:

- Moisture content of the material: – dry material produce higher CBR values than wet or saturated material,

- Grading of the material: – presence of an individual particle of stone (or any hard material) in the line of the cone might mislead the results to a high CBR contrary to the actual quality.

- Inclination of the instrument: – give erroneous results by affecting the direction of the cone and free fall of the hammer.

- Empirical corelations:- the test does not directly measure soil strength parameters like CBR or modulus—it relies on empirical correlations, which may not be accurate for all soil conditions or regions.

- Limited Depth and Data Resolution:-the test typically evaluates only the upper 800mm* or so of the soil profile and may miss deeper weak layers unless conducted in test pits.

*NOTE: The depth of 800mm is selected as the effect of traffic loading is very marginal beyond 800mm of road depth.

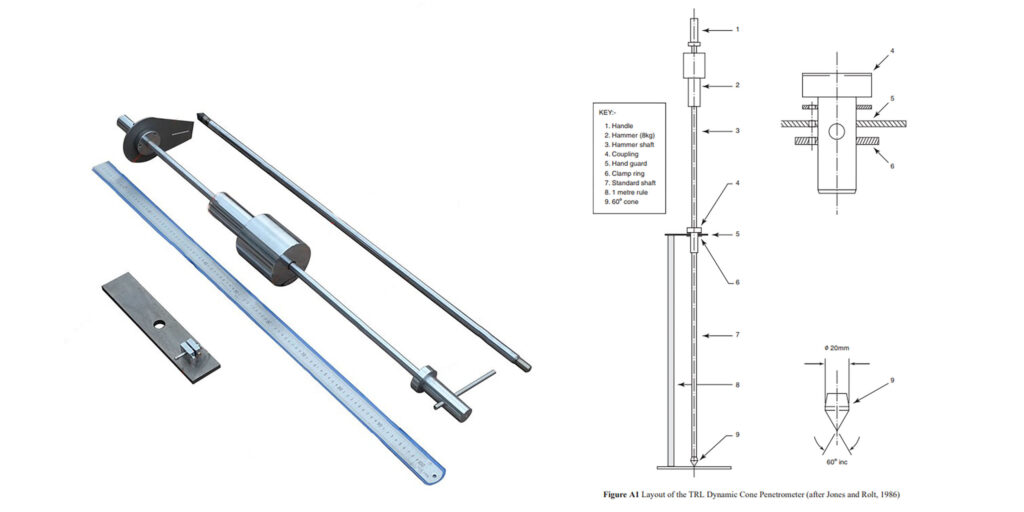

Test Procedure – According to TRL 113

- Assemble the instrument per the instruction manual and position it on the leveled surface at the point to be tested.

- Hold the instrument vertically on the ground, place the cone on the surface and take the initial reading on the scale rule.

- Lift the hammer to its upper limit and allow it to drop freely (10 times for hard layers and 5 or 3 times for weak layers) and record the scale reading after the number of blows.

- Continue with penetration (by applying the chosen number of blows) and recording scale readings until a total penetration of 800mm or more is achieved

- Plot a graph of cumulative blows on x-axis and cumulative penetration on y-axis and join the points by straight line.

- Calculate the DCP value, otherwise refered to as the DCP Index (DCPI), whose units are mm per blow, at each change of slope as follows:

![]()

- Interpolate the CBR values on the DCP/CBR Correlation chart or by using empirical formula.

Presentation of Results and Interpretation

To determine the CBR for a certain soil layer, proceed as follows:

- Plot a graph of cumulative number of blows against the penetration depth (in mm) – a sample data capture form and graph is attached below.

- Draw the line of best fit on this points. In case the DCP test goes through layers with significant CBR differences, the plotted points will have different slopes. In this case, more than one straight line will be drawn, each representing a different soil layer. The form attached below represents a DCP test that went through two separate soil layers.

- Determine the DCP of each layer using the formula shown under point number 6 above of the test procedure.

- From the DCP value obtained above, the CBR of the soil can be determined by either of the following methods:

- Directly reading off the CBR from a DCP/CBR correlation chart,

- Using formulas* that present empirical correlations between DCP and CBR. For instance, according to the report number TRL 587, published by the UK Transport Research Laboratory (TRL), titled The correlation between the CBR value and penetrability of pavement construction materials, the relationship between CBR and DCP is given by the general formula:

![]()

Where A and B are regression constants that depend on the type of soil. It has been determined, however, that the values of 2.81 for A and -1.32 for B are applicable for all soil types and, therefore, the formula above can be generalized as:

![]()

With the DCP value obtained from the graph, you can easily obtain the CBR of the soil by solving the equation.

As an example, by reading off the CBR values directly from the DCP/CBR correlation chart, we get a CBR of 100% for layer 1(3.1mm/blow penetration) and 40% for layer 2(7.3mm/blow penetration), whereas by applying the correlation formula above, we get CBRs of 145.1% and 46.8% respectively. Therefore, using the empirical relationship between DCP and CBR gives more accurate results than reading off the CBR from the chart.

Conclusion

In certain circumstances, engineers need to determine the CBR of underlying soil conditions insitu. In this case, the DCP test is the most ideal test. Apart from determining the strength of subgrade and pavement layers, the DCP test can also be used to determine the thicknesses of different pavement layers.

Quite informative!